The benefits of automated egg chicken cage farming: Automated egg chicken farming has the advantages of saving land, reducing environmental pollution, reducing feeding costs, improving investment utilization, and labor productivity. The density of automated egg chicken farming equipment can reach 4813-60 chickens? M2, with a feed to egg ratio of 212-215:1, and a mortality rate of less than 15%, compared to three-layer full step cage farming, it can save 63148% of land and improve labor productivity by 160-290%. High density stacked cage breeding of laying hens has the advantages of saving land, reducing environmental pollution, reducing feeding costs, improving investment utilization rate and labor productivity. It is a new intensive and cost-effective breeding management model for laying hens, which is in line with the trend of modern laying hens production and development. Environmental control facilities are provided. In summer, a longitudinal ventilation wet curtain cooling system is used for negative pressure ventilation in the chicken coop, while in other seasons, the wet curtain water pump is discontinued. In addition to installing a wet curtain fan ventilation system, the breeding house also needs to use a coal fired positive pressure and equal heat uniform air supply system during the low temperature period in winter to ensure the normal growth of the chicks. Install an intelligent data collection and environmental management self-control system in the chicken coop to achieve automatic control of lighting, ventilation, cooling, and heating inside the coop. The feeding management system [1] is different from general chicken coops due to the shape of the cage and environmental control factors. There are two ways to expand the flock of laying hens during the brooding and breeding period. One is to expand the flock from one layer to the other layers, which is a vertical expansion system; One is to vertically expand the flock along the chicken coop from one end to each layer, which is a horizontal expansion system. Vertical expansion, as it always occupies one or more layers, each layer's self-contained feeding, drinking, and fecal cleaning systems can operate at full capacity, with high equipment and energy utilization rates, and should be prioritized. When expanding horizontally, the chicken body is dense, which can achieve effective environmental control and is suitable for areas with harsh climate conditions. Due to the towering and dense cages, the transfer operation of laying hens is relatively difficult, and the mortality rate of chickens is high. Therefore, strict operating procedures should be formulated and the transfer should be carried out at night. Feeding, defecation, egg collection, and epidemic prevention in a stacked cage are controlled by a timing device. The feeding control program is set based on the feed intake of laying hens during different feeding periods, and the feed is sent to the feeding trough through pipes and spiral devices from the feeding tower. Chicken manure is discharged from the outside of the house through a horizontal manure belt and a horizontal manure cleaning ditch at the end of the house. The manure is cleaned once in the morning and once in the afternoon. The automatic egg collection system can complete the transportation, cleaning, and disinfection of eggs. In actual production, rail cars can also be installed on cages for manual egg collection. By connecting to the automatic dosing device of the drinking water system, disease prevention work for chicken flocks can be conveniently carried out. The layered cage breeding process is highly mechanized and automated, and adopts a responsibility system in production organization and management, resulting in high labor efficiency for personnel. When the egg production rate in adult chicken coops is below 80%, the six row cages in the entire coop are managed by four people in zones (mainly for manual egg collection), with a management quota of 15000 per person. During the peak egg production period, one person will manage one row, which means each person will manage 10000 laying hens. The key to the success or failure of stacked cage farming in environmental control lies in the control of the indoor environment. The dense chicken body generates a large amount of heat and harmful gases, and effective environmental control measures are taken to control the temperature and air quality of the house. The 200000 egg chicken farm in Luoniushan, Haikou adopts a longitudinal ventilation wet curtain cooling system, which successfully solves the environmental problems of high-density stacked cages in tropical areas in summer. The main parameters for controlling the environment inside the chicken coop are temperature and light, and the number of fans turned on is adjusted according to the meteorological conditions outside the coop, with mechanical ventilation.

ABOUT US

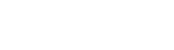

Located in the industrial cluster area of Xiuwu County, Jiaozuo City

Constructing an automatic control system for large-scale aquaculture farms

Provide solutions for the planning, design, and construction of aquaculture farms

PRODUCT CENTER

Strong product research and development capabilities, assembly processes

Exquisite production and construction team

Won the long-term trust and support of customers for the company

Cooperation Cases

At present, the sales network is all over Chinese Mainland

Business extension to Mongolia, multiple countries in Africa, as well as countries such as Myanmar and Indonesia

The company has established long-term cooperative relationships with multiple well-known group companies both domestically and internationally

video center

Located in the industrial cluster area of Xiuwu County, Jiaozuo City

Constructing an automatic control system for large-scale aquaculture farms

Provide solutions for the planning, design, and construction of aquaculture farms

News information

Located in the industrial cluster area of Xiuwu County, Jiaozuo City

Constructing an automatic control system for large-scale aquaculture farms

Provide solutions for the planning, design, and construction of aquaculture farms

video

Service hotline

0391-7180002

-

contact:MR.WANG

-

tel:18595705141

-

email:729019658@qq.com

-

address:North side of West Section of Huafang Road, Industrial Agglomeration Zone, Xiuwu County, Jiaozuo City